Tel:+86-7103723830

Email:biz.hb@jhchemical.com

FAX:

FACTORY:No. 32, Tianshun Avenue, Xiangcheng Economic Development Zone, Xiangyang City, Hubei Province,China

Production Manager:Laura Lau

Tel:+86 19571296744

Sales Manager:Tiffany Yang

Tel:+86-13871702573

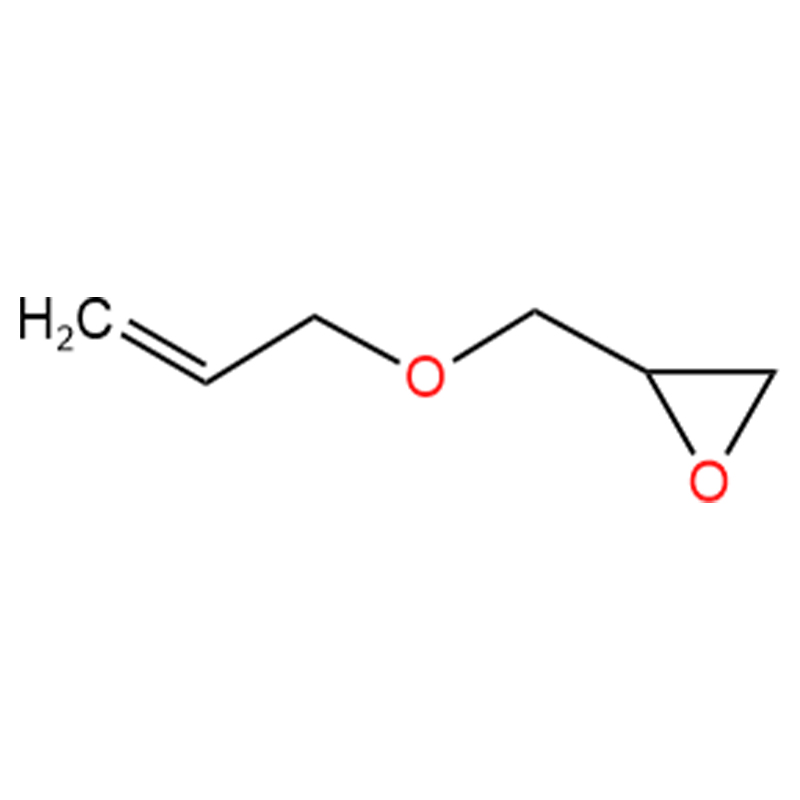

In the specialized field of epoxy chemistry, precision and purity are the cornerstones of quality. Jinghong, a leading Allyl Glycidyl Ether 680 supplier and custom epoxy compound manufacturer based in China, has emerged as a trusted name for industries demanding high-performance, reliable materials. By combining advanced synthesis techniques, rigorous quality control, and a commitment to customization, Jinghong delivers epoxy compounds that meet the exacting standards of aerospace, electronics, coatings, and advanced manufacturing sectors.

As a China-based manufacturer, Jinghong leverages cutting-edge production facilities and a team of experienced chemists to produce Allyl Glycidyl Ether 680—a key monomer renowned for its reactivity, versatility, and compatibility with various epoxy systems. This compound’s unique structure enables it to enhance cross-linking density, improve thermal stability, and boost mechanical properties in resins, adhesives, and composites. Jinghong’s high-purity epoxy compound formulations ensure minimal impurities, reducing the risk of defects in end-use applications.

One of Jinghong’s standout strengths is its custom epoxy compound service. Recognizing that every client has distinct requirements—whether it’s adjusting viscosity, modifying cure speed, or integrating specific functional groups—the company collaborates closely with partners to develop tailored solutions. From lab-scale prototyping to large-volume production, Jinghong’s R&D team ensures formulations align with performance goals, regulatory standards, and cost constraints. This flexibility has made Jinghong a preferred supplier for businesses seeking competitive advantages through material innovation.

Jinghong’s dedication to quality is unmatched. Each batch of Allyl Glycidyl Ether 680 undergoes multi-stage purity testing, including gas chromatography (GC), nuclear magnetic resonance (NMR) spectroscopy, and moisture content analysis. These measures guarantee consistency, enabling clients to achieve repeatable results in their processes. The company’s adherence to ISO 9001 and REACH compliance further underscores its commitment to excellence.

Cost-effectiveness is another hallmark of Jinghong’s offerings. As a China-based manufacturer, the company optimizes production efficiency without compromising on raw material quality or environmental standards. This balance allows Jinghong to offer competitive pricing, making premium epoxy compounds accessible to a broader range of industries.

For niche applications or emerging technologies, Jinghong excels in rapid formulation development. Whether it’s a UV-curable epoxy, a flame-retardant adhesive, or a bio-based resin, the company’s R&D capabilities enable it to pioneer solutions that address evolving market demands. Collaborations with universities and research institutes further strengthen Jinghong’s position as an industry leader.

Sustainability is also embedded in Jinghong’s ethos. The company offers eco-friendly epoxy compounds with reduced volatile organic compounds (VOCs) and recyclable packaging options. By supporting green chemistry initiatives, Jinghong helps clients meet environmental regulations while maintaining performance.

Jinghong’s reputation as a custom epoxy compound manufacturer is reinforced by its customer-centric approach. The company provides technical support throughout the product lifecycle, from formulation advice to troubleshooting during scale-up. This partnership mindset fosters long-term collaborations with clients seeking to differentiate their offerings in competitive markets.

In industries where safety is paramount, such as aerospace or medical devices, Jinghong’s epoxy compounds comply with stringent standards like UL, FDA, and military specifications. This compliance ensures seamless integration into critical applications.

Whether for prototyping, pilot production, or full-scale manufacturing, Jinghong’s flexible production capabilities cater to diverse needs. The company’s ability to adapt to changing market dynamics—such as shifts toward lightweight materials or renewable resources—positions it as a forward-thinking supplier.

In conclusion, Jinghong is redefining the standards of epoxy compound manufacturing in China. By blending scientific expertise, customization, and a focus on sustainability, the brand empowers industries to innovate while ensuring reliability. For businesses seeking a partner that values precision, adaptability, and collaboration, Jinghong is the ultimate choice in the epoxy chemistry landscape.